-

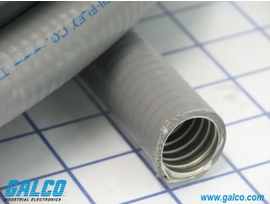

22101Electri-Flex Conduit, LA Series

22101Electri-Flex Conduit, LA Series Item Number22101MFG Item NumberLA-12SeriesLAProduct DescriptionCONDUIT, 3/4in., LA, GRAY, JACKETEDSpecifications

Item Number22101MFG Item NumberLA-12SeriesLAProduct DescriptionCONDUIT, 3/4in., LA, GRAY, JACKETEDSpecificationsSpecifications Trade Size 3/4 " Diameter 1.05 " Feet/Pkg. 100 Inside Bend Radius 4.2 " Conduit Material Steel Color Gray Temperature Range (F) -4-140 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

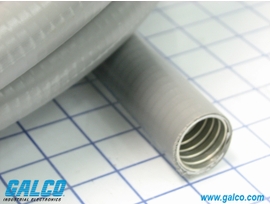

12102Electri-Flex Conduit, LT Series

12102Electri-Flex Conduit, LT Series Item Number12102MFG Item NumberLT-12-100SeriesLTProduct DescriptionConduit, 3/4in., LT, Gray, Jacketed,Specifications

Item Number12102MFG Item NumberLT-12-100SeriesLTProduct DescriptionConduit, 3/4in., LT, Gray, Jacketed,SpecificationsSpecifications Trade Size 3/4 " Diameter 1.05 " Feet/Pkg. 100 Inside Bend Radius 2.5 " Conduit Material Steel Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

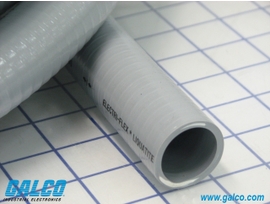

81011Electri-Flex Conduit, NM Series

81011Electri-Flex Conduit, NM Series Item Number81011MFG Item NumberNM-11SeriesNMProduct DescriptionConduit, 1/2in., NM, Gray, Non-Metal,Specifications

Item Number81011MFG Item NumberNM-11SeriesNMProduct DescriptionConduit, 1/2in., NM, Gray, Non-Metal,SpecificationsSpecifications Trade Size 1/2 " Diameter 0.84 " Feet/Pkg. 100 ' Inside Bend Radius 3.25 " Conduit Material Polyvinyl Chloride (PVC) Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

13102Electri-Flex Conduit, LT Series

13102Electri-Flex Conduit, LT Series Item Number13102MFG Item NumberLT-13SeriesLTProduct DescriptionConduit, 1in., LT, Metallic Jacketed,Specifications

Item Number13102MFG Item NumberLT-13SeriesLTProduct DescriptionConduit, 1in., LT, Metallic Jacketed,SpecificationsSpecifications Trade Size 1 " Diameter 1.32 " Feet/Pkg. 100 Inside Bend Radius 3 " Conduit Material Steel Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

11101Electri-Flex Conduit, LT Series

11101Electri-Flex Conduit, LT Series Item Number11101MFG Item NumberLT-11SeriesLTProduct DescriptionFlexible Metallic Conduit, 1/2in. Gry,Specifications

Item Number11101MFG Item NumberLT-11SeriesLTProduct DescriptionFlexible Metallic Conduit, 1/2in. Gry,SpecificationsSpecifications Trade Size 1/2 " Diameter 0.84 " Feet/Pkg. 100 Inside Bend Radius 2 " Conduit Material Steel Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

80132Electri-Flex Conduit, EF Series

80132Electri-Flex Conduit, EF Series Item Number80132MFG Item NumberEF-13SeriesEFProduct DescriptionConduit, 1in., EF, Gray, Jacketed,Specifications

Item Number80132MFG Item NumberEF-13SeriesEFProduct DescriptionConduit, 1in., EF, Gray, Jacketed,SpecificationsSpecifications Trade Size 1 " Diameter 1.32 " Feet/Pkg. 100 Inside Bend Radius 3 " Conduit Material Steel Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

81032Electri-Flex Conduit, NM Series

81032Electri-Flex Conduit, NM Series Item Number81032MFG Item NumberNM-13SeriesNMProduct DescriptionConduit, 1in., Non-Metallic, GraySpecifications

Item Number81032MFG Item NumberNM-13SeriesNMProduct DescriptionConduit, 1in., Non-Metallic, GraySpecificationsSpecifications Trade Size 1 " Diameter 1.32 " Feet/Pkg. 100 ' Inside Bend Radius 6.5 " Conduit Material Polyvinyl Chloride (PVC) Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

EFC050Thomas & Betts Conduit, Type B Liquidtight Series

EFC050Thomas & Betts Conduit, Type B Liquidtight Series Item NumberEFC050MFG Item NumberEFC050SeriesType B LiquidtightProduct DescriptionFlexible Tubing, 1/2in., Non-MetallicSpecifications

Item NumberEFC050MFG Item NumberEFC050SeriesType B LiquidtightProduct DescriptionFlexible Tubing, 1/2in., Non-MetallicSpecificationsSpecifications Trade Size 1/2 " Diameter 0.642 " Color Black Temperature Range (F) 2-140 °F Oil Resistant No Acid Resistant No Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

64112BHalex Conduit

64112BHalex Conduit Item Number64112BMFG Item Number64112BProduct DescriptionRIGID 1-1/4in. 90DEG ELBOW (UPC)Specifications

Item Number64112BMFG Item Number64112BProduct DescriptionRIGID 1-1/4in. 90DEG ELBOW (UPC)SpecificationsSpecifications Trade Size 1-1/4 " Conduit Material Steel Hazardous Rated No Composition Metallic Angle (degrees) 90 ° Min UL Radius 11.375 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

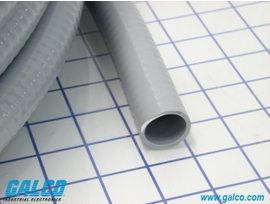

81022Electri-Flex Conduit, NM Series

81022Electri-Flex Conduit, NM Series Item Number81022MFG Item NumberNM-12SeriesNMProduct DescriptionConduit, 3/4in., NM, Gray,Specifications

Item Number81022MFG Item NumberNM-12SeriesNMProduct DescriptionConduit, 3/4in., NM, Gray,SpecificationsSpecifications Trade Size 3/4 " Diameter 1.05 " Feet/Pkg. 100 ' Inside Bend Radius 4.25 " Conduit Material Polyvinyl Chloride (PVC) Color Gray Temperature Range (F) -4-176 °F Oil Resistant Yes Acid Resistant Yes Liquid Tight Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Conduit

An electrical conduit is a tube used to protect and route wires and cables in buildings, structures, or cabinets. A variety of materials and designs are used to make conduits, each determined by application requirements.

Conduit is typically made of metal or plastic and is generally rigid. Conduit provides excellent protection to enclosed wires and cables from impact, moisture, and other hazardous materials, in both interior and exterior environments. Conduits can also be made to be submersible or wrapped or coated with materials to shield conductors from electromagnetic or radio frequency interference.

Because most conduit is rigid, special fittings - elbows, bends, etc. - are needed to guide cabling around corners or other specific directions. If permitted by electrical codes, a flexible conduit is available to isolate wiring from vibrations or simplify the number of fittings needed to wire a structure or facility.

Conduit is typically made of metal or plastic and is generally rigid. Conduit provides excellent protection to enclosed wires and cables from impact, moisture, and other hazardous materials, in both interior and exterior environments. Conduits can also be made to be submersible or wrapped or coated with materials to shield conductors from electromagnetic or radio frequency interference.

Because most conduit is rigid, special fittings - elbows, bends, etc. - are needed to guide cabling around corners or other specific directions. If permitted by electrical codes, a flexible conduit is available to isolate wiring from vibrations or simplify the number of fittings needed to wire a structure or facility.