-

ACS355-03U-08A8-4+J400ABB Drives, ACS355 Series

ACS355-03U-08A8-4+J400ABB Drives, ACS355 Series Item NumberACS355-03U-08A8-4+J400MFG Item NumberACS355-03U-08a8-4+J400SeriesACS355Product DescriptionDrive, AC, 5HP, 480V, 8.8A, CT, OPSpecifications

Item NumberACS355-03U-08A8-4+J400MFG Item NumberACS355-03U-08a8-4+J400SeriesACS355Product DescriptionDrive, AC, 5HP, 480V, 8.8A, CT, OPSpecificationsSpecifications Input Phase 3 HP (Constant Torque Rating) 5 hp Amps (Constant Torque Rating) 8.8 A Closed Loop Optional AC Line Regenerative No Operator Controls Keypad Included IP Rating IP20 Motor Control-Max Level Open Loop Vector (Sensorless Vector) Mounting Panel Input Range Voltage (AC) 380-480 VAC Max Frequency 600 Hz Frame Size R1 Depth 6.34 " Width 2.76 " Height 7.95 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

KBMM-225DKB Electronics Drives, KBMM Series

KBMM-225DKB Electronics Drives, KBMM Series Item NumberKBMM-225DMFG Item Number9451SeriesKBMMProduct DescriptionKB ElectronicsSpecifications

Item NumberKBMM-225DMFG Item Number9451SeriesKBMMProduct DescriptionKB ElectronicsSpecificationsSpecifications Input Current (AC) 12 A Output Armature Voltage (DC) 90 VDC, 180 VDC Max HP @ 90 VDC Armature 3 hp Input Phase 1 Output Field Current (DC) 1 A Regen No Operator Controls Not Available Temperature Range (F) 32-113 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

KBMM-125KB Electronics Drives, KBMM Series

KBMM-125KB Electronics Drives, KBMM Series Item NumberKBMM-125MFG Item Number9449SeriesKBMMProduct DescriptionKB ElectronicsSpecifications

Item NumberKBMM-125MFG Item Number9449SeriesKBMMProduct DescriptionKB ElectronicsSpecificationsSpecifications Input Current (AC) 12 A Output Armature Voltage (DC) 90 VDC Max HP @ 90 VDC Armature 1.5 hp Input Phase 1 Output Field Current (DC) 1 A Max Armature Current (DC) 8 A Nominal Input VAC 120 VAC Regen No Operator Controls Not Available Temperature Range (F) 32-113 °F Nominal Armature VDC 90 VDC AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

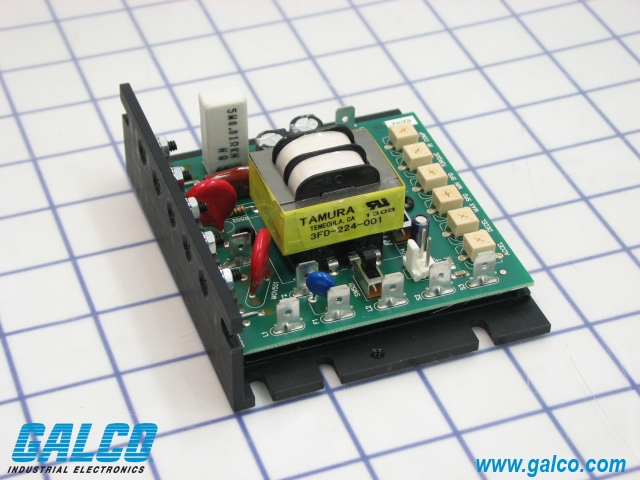

MM23001CMinarik Drives Drives, MM23000C Series

MM23001CMinarik Drives Drives, MM23000C Series Item NumberMM23001CMFG Item NumberMM23001CSeriesMM23000CProduct DescriptionDrive, DC, 5A, 115/230VAC Input,Specifications

Item NumberMM23001CMFG Item NumberMM23001CSeriesMM23000CProduct DescriptionDrive, DC, 5A, 115/230VAC Input,SpecificationsSpecifications Output Armature Voltage (DC) 0-90 VDC, 0-180 VDC Max HP @ 90 VDC Armature 1 hp Max HP @ 180 VDC Armature 2 hp Input Phase 1 Output Field Current (DC) 1 A Max Armature Current (DC) 10 A Feedback Types Armature Operator Controls Built In Temperature Range (F) 50-131 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

ACH-CP-BABB Drives

ACH-CP-BABB Drives Item NumberACH-CP-BMFG Item NumberACH-CP-BProduct DescriptionHVAC Advanced Control Panel forAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberACH-CP-BMFG Item NumberACH-CP-BProduct DescriptionHVAC Advanced Control Panel forAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

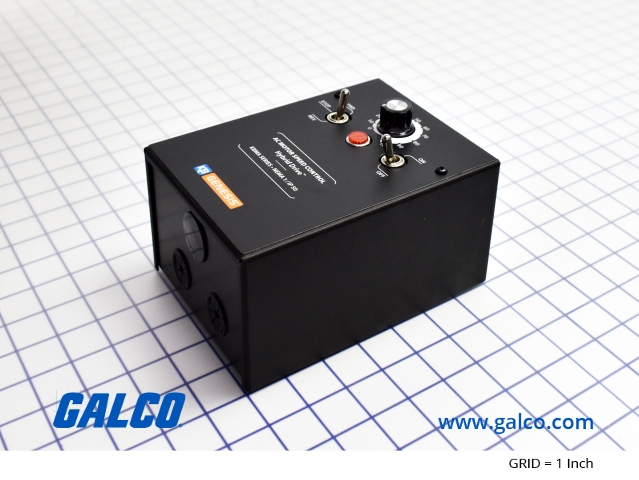

KBMA-24DW/FSRKB Electronics Drives, KBMA Series

KBMA-24DW/FSRKB Electronics Drives, KBMA Series Item NumberKBMA-24DW/FSRMFG Item Number9640SeriesKBMAProduct DescriptionNEMA-1 AC INVERTER, 115/230 VAC 1P,Specifications

Item NumberKBMA-24DW/FSRMFG Item Number9640SeriesKBMAProduct DescriptionNEMA-1 AC INVERTER, 115/230 VAC 1P,SpecificationsSpecifications Input Phase 1 HP (Constant Torque Rating) 1 hp Amps (Constant Torque Rating) 3.6 A Braking Type DC Injection Closed Loop No AC Line Regenerative No Operator Controls Built In IP Rating IP50 NEMA Rating NEMA 1 Motor Control-Max Level Open Loop Vector (Sensorless Vector) Mounting Panel Input Range Voltage (AC) 98-132 VAC, 177-264 VAC Max Frequency 60 Hz AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

ACS355-03U-07A5-2+J400ABB Drives, ACS355 Series

ACS355-03U-07A5-2+J400ABB Drives, ACS355 Series Item NumberACS355-03U-07A5-2+J400MFG Item NumberACS355-03U-07A5-2+J400SeriesACS355Product DescriptionDrive, AC, 2HP, 240V, 7.5A, CT, OPSpecifications

Item NumberACS355-03U-07A5-2+J400MFG Item NumberACS355-03U-07A5-2+J400SeriesACS355Product DescriptionDrive, AC, 2HP, 240V, 7.5A, CT, OPSpecificationsSpecifications Input Phase 3 HP (Constant Torque Rating) 2 hp Amps (Constant Torque Rating) 7.5 A Closed Loop Optional AC Line Regenerative No Operator Controls Keypad Included IP Rating IP20 Motor Control-Max Level Open Loop Vector (Sensorless Vector) Mounting Panel Nominal Input VAC 240 VAC Input Range Voltage (AC) 200-240 VAC Max Frequency 600 Hz Frame Size R1 Depth 6.34 " Width 2.76 " Height 7.95 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

KBVF-24DKB Electronics Drives, KBVF Series

KBVF-24DKB Electronics Drives, KBVF Series Item NumberKBVF-24DMFG Item Number9979SeriesKBVFProduct DescriptionKB ElectronicsSpecifications

Item NumberKBVF-24DMFG Item Number9979SeriesKBVFProduct DescriptionKB ElectronicsSpecificationsSpecifications Input Phase 1 HP (Constant Torque Rating) 1 hp Amps (Constant Torque Rating) 4 A Braking Type DC Injection Closed Loop No AC Line Regenerative Yes Operator Controls Sold Separately, See Accessories IP Rating IP20 Motor Control-Max Level Open Loop Vector (Sensorless Vector) Mounting Panel Input Range Voltage (AC) 98-132 VAC, 177-264 VAC Max Frequency 60 Hz AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

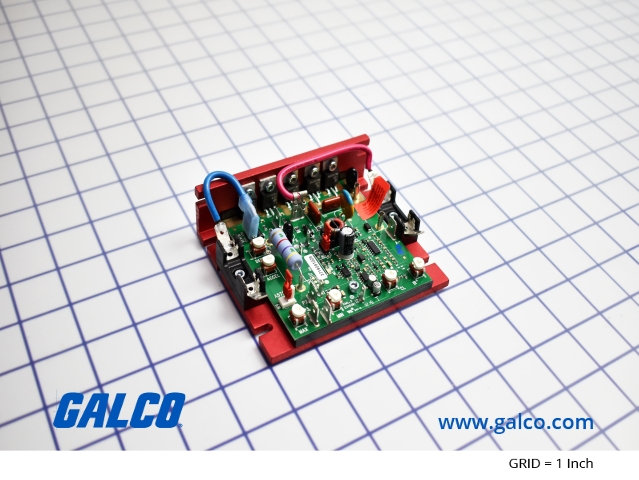

KBIC-240KB Electronics Drives, KBIC Series

KBIC-240KB Electronics Drives, KBIC Series Item NumberKBIC-240MFG Item Number9428SeriesKBICProduct DescriptionKB ElectronicsSpecifications

Item NumberKBIC-240MFG Item Number9428SeriesKBICProduct DescriptionKB ElectronicsSpecificationsSpecifications Input Current (AC) 9 A Output Armature Voltage (DC) 180 VDC Max HP @ 180 VDC Armature 2 hp Input Phase 1 Output Field Current (DC) 1 A Max Armature Current (DC) 6 A Nominal Input VAC 240 VAC Regen No Operator Controls Not Available Temperature Range (F) 32-113 °F Nominal Armature VDC 180 VDC AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

ACS355-03U-05A6-4+J400ABB Drives, ACS355 Series

ACS355-03U-05A6-4+J400ABB Drives, ACS355 Series Item NumberACS355-03U-05A6-4+J400MFG Item NumberACS355-03U-05A6-4+J400SeriesACS355Product DescriptionDrive, AC, 3HP, 480V, 5.6A, CT, OPSpecifications

Item NumberACS355-03U-05A6-4+J400MFG Item NumberACS355-03U-05A6-4+J400SeriesACS355Product DescriptionDrive, AC, 3HP, 480V, 5.6A, CT, OPSpecificationsSpecifications Input Phase 3 HP (Constant Torque Rating) 3 hp Amps (Constant Torque Rating) 5.6 A Closed Loop Optional AC Line Regenerative No Operator Controls Keypad Included IP Rating IP20 Motor Control-Max Level Open Loop Vector (Sensorless Vector) Mounting Panel Input Range Voltage (AC) 380-480 VAC Max Frequency 600 Hz Frame Size R1 Depth 6.34 " Width 2.76 " Height 7.95 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Drives

Drives are electromechanical systems that employ an electric motor as the prime mover in a system to control the motion and processes of various machines. The primary function of a drive is to provide a precise amount of electric energy to a motor so that its speed matches exactly what is required by its process.

Drives are most commonly referred to as variable speed drives, adjustable speed drives, variable frequency drives, and adjustable frequency drives. No matter which term is used, the drive’s primary task is to control the speed of an electric motor.

AC and DC Drives are available in a wide variety of frame sizes, with different horsepower ratings to cover any industrial process, large or small.

Drives are most commonly referred to as variable speed drives, adjustable speed drives, variable frequency drives, and adjustable frequency drives. No matter which term is used, the drive’s primary task is to control the speed of an electric motor.

AC and DC Drives are available in a wide variety of frame sizes, with different horsepower ratings to cover any industrial process, large or small.