-

PX3PLX01Veris Industries Transducers, PX3 Series

PX3PLX01Veris Industries Transducers, PX3 Series Item NumberPX3PLX01MFG Item NumberPX3PLX01SeriesPX3Product DescriptionPressure, Dry, Panel, LCD, 0-1 In WCSpecifications

Item NumberPX3PLX01MFG Item NumberPX3PLX01SeriesPX3Product DescriptionPressure, Dry, Panel, LCD, 0-1 In WCSpecificationsSpecifications Type Digital Display Gauge Pressure Range (Gauge) 0-250 pa Input 12-30 VDC Output 4-20 mA Electrical Connection Screw Terminal NEMA Rating NEMA 4 IP Rating IP65 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

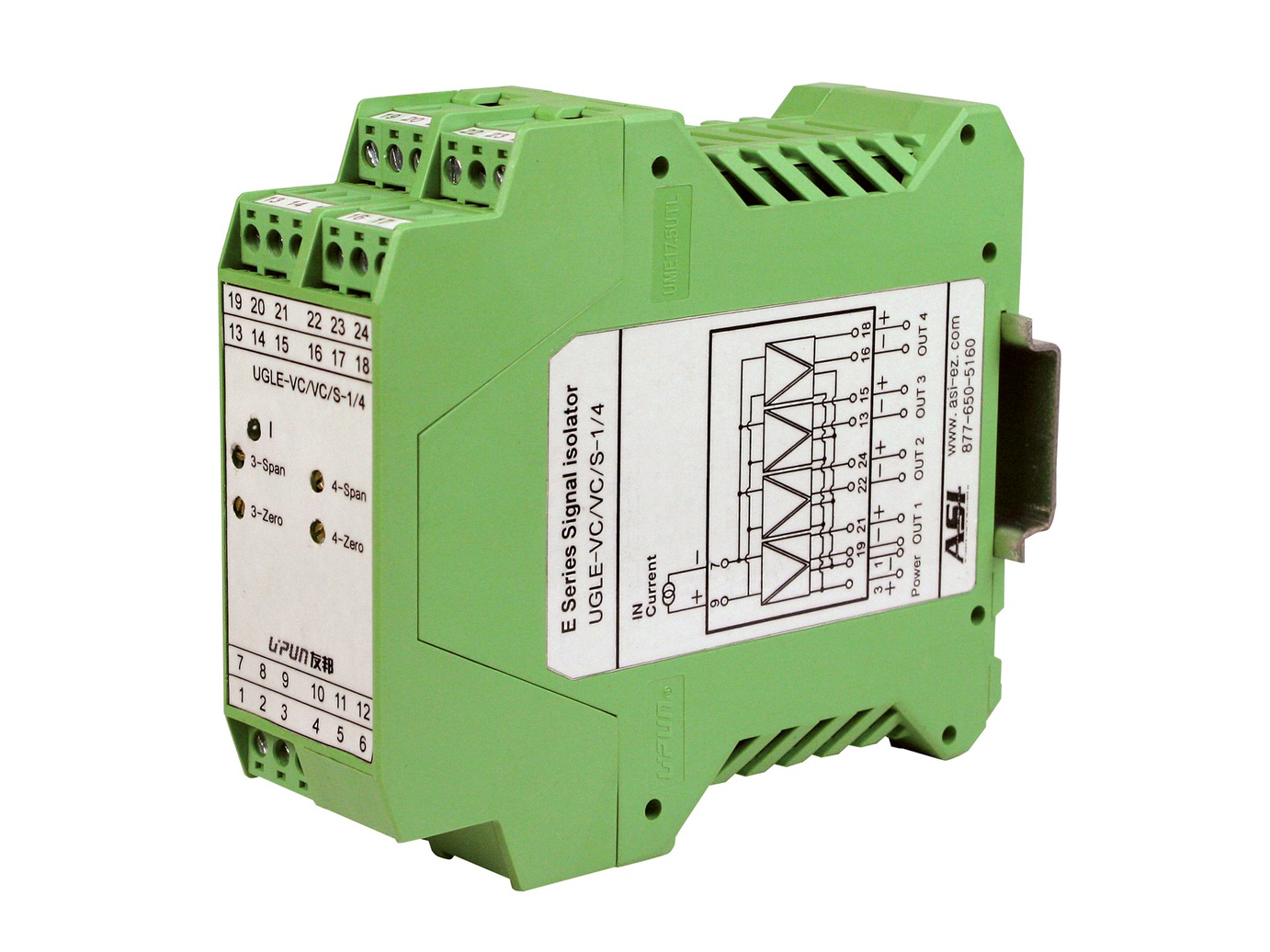

ASI451124ASI-Automation Systems Interconnect Transducers

ASI451124ASI-Automation Systems Interconnect Transducers Item NumberASI451124MFG Item NumberASI451124Product Description4-20Ma Analog Signal Splitter,Specifications

Item NumberASI451124MFG Item NumberASI451124Product Description4-20Ma Analog Signal Splitter,SpecificationsSpecifications Supply Voltage 24 VDC Input Signal Milliamps (mAAC) Output Signal Milliamps (mAAC) Mounting DIN Rail AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

961-070-000Bellofram Transducers, Type 1000 Series

961-070-000Bellofram Transducers, Type 1000 Series Item Number961-070-000MFG Item Number961-070-000SeriesType 1000Product DescriptionElectro-Pneumatic, Type I/P, 3-15 PSIGSpecifications

Item Number961-070-000MFG Item Number961-070-000SeriesType 1000Product DescriptionElectro-Pneumatic, Type I/P, 3-15 PSIGSpecificationsSpecifications Type General Industrial (Unamplified) Pressure Range (Gauge) 3-15 psi Input 4-20 mA Electrical Connection Wire Lead AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

2091100PG2M11A1Setra Transducers, 209 Series

2091100PG2M11A1Setra Transducers, 209 Series Item Number2091100PG2M11A1MFG Item Number2091100PG2M11A1Series209Product DescriptionGauge Pressure Transducer, 0-100Specifications

Item Number2091100PG2M11A1MFG Item Number2091100PG2M11A1Series209Product DescriptionGauge Pressure Transducer, 0-100SpecificationsSpecifications Type Differential Pressure Range (Gauge) 0-100 psi Input 9-30 VDC Output 4-20 mA Electrical Connection Multiconductor Cable Electrical Wire Length 2 ' Temperature Range '-40-185 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

ASI451141ASI-Automation Systems Interconnect Transducers

ASI451141ASI-Automation Systems Interconnect Transducers Item NumberASI451141MFG Item NumberASI451141Product DescriptionAnalog Signal Splitter, 3-WaySpecifications

Item NumberASI451141MFG Item NumberASI451141Product DescriptionAnalog Signal Splitter, 3-WaySpecificationsSpecifications Supply Voltage 24 VDC Input Signal Milliamps (mAAC) Output Signal Milliamps (mAAC) Mounting DIN Rail AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

857-809Wago Transducers, 857 Series

857-809Wago Transducers, 857 Series Item Number857-809MFG Item Number8570809Series857Product DescriptionJUMPFLEX signal conditioner,Specifications

Item Number857-809MFG Item Number8570809Series857Product DescriptionJUMPFLEX signal conditioner,SpecificationsSpecifications Supply Voltage 24 VDC Input Signal Potentiometer Output Signal Milliamps (mADC) Number of Channels 3 Mounting DIN Rail AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

2091Z01PV2M1102Setra Transducers, 209 Series

2091Z01PV2M1102Setra Transducers, 209 Series Item Number2091Z01PV2M1102MFG Item Number2091Z01PV2M1102Series209Product DescriptionGauge Pressure Transducer, 0 toSpecifications

Item Number2091Z01PV2M1102MFG Item Number2091Z01PV2M1102Series209Product DescriptionGauge Pressure Transducer, 0 toSpecificationsSpecifications Type Differential Pressure Range (Gauge) 0-14.7 psi Input 9-30 VDC Output 4-20 mA Electrical Connection Multiconductor Cable Electrical Wire Length 2 ' Temperature Range '-40-185 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

2091100PG2M1102Setra Transducers, 209 Series

2091100PG2M1102Setra Transducers, 209 Series Item Number2091100PG2M1102MFG Item Number2091100PG2M1102Series209Product DescriptionGauge Pressure Transducer, 0-100Specifications

Item Number2091100PG2M1102MFG Item Number2091100PG2M1102Series209Product DescriptionGauge Pressure Transducer, 0-100SpecificationsSpecifications Type Differential Pressure Range (Gauge) 0-100 psi Input 9-30 VDC Output 4-20 mA Electrical Connection Multiconductor Cable Electrical Wire Length 2 ' Temperature Range '-40-185 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

961-112-000Bellofram Transducers, Type 1000 Series

961-112-000Bellofram Transducers, Type 1000 Series Item Number961-112-000MFG Item Number961-112-000SeriesType 1000Product DescriptionTransducerSpecifications

Item Number961-112-000MFG Item Number961-112-000SeriesType 1000Product DescriptionTransducerSpecificationsSpecifications Type General Industrial (Amplified) Pressure Range (Gauge) 3-120 psi Input 0-10 VAC Electrical Connection Wire Lead AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

857-400Wago Transducers, 857 Series

857-400Wago Transducers, 857 Series Item Number857-400MFG Item Number8570400Series857Product DescriptionJUMPFLEX signal conditioner,Specifications

Item Number857-400MFG Item Number8570400Series857Product DescriptionJUMPFLEX signal conditioner,SpecificationsSpecifications Supply Voltage 24 VDC Number of Channels 3 Mounting DIN Rail AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Transducers

Transducers are used to convert one form of energy into another.

There are two primary types of transducers: sensors and actuators. An electronic thermometer, for example, is a sensor that detects heat energy and reports temperature. A transducer is needed to convert the heat energy into an electrical signal that can be displayed on a gauge or meter. Actuators, on the other hand, receive an electrical input signal and perform a physical action. Transduction occurs when the signal is converted into a force.

Transducers are found in most automation, measurement and control applications. They are commonly used to report force, pressure, position or current values. They are also used to convert signals for measurement.

There are two primary types of transducers: sensors and actuators. An electronic thermometer, for example, is a sensor that detects heat energy and reports temperature. A transducer is needed to convert the heat energy into an electrical signal that can be displayed on a gauge or meter. Actuators, on the other hand, receive an electrical input signal and perform a physical action. Transduction occurs when the signal is converted into a force.

Transducers are found in most automation, measurement and control applications. They are commonly used to report force, pressure, position or current values. They are also used to convert signals for measurement.