WE’RE CELEBRATING WITH FREE GROUND

SHIPPING ON WEB ORDERS OVER $99!

Terms and Conditions Apply

Here’s a glimpse of what’s new:

• Historical Orders & Invoices

• Real-Time Shipping & Tracking

• Effortless Re-ordering

• Streamlined Account Registration

Wednesday, September 18, 2024

Join us for an unforgettable day of

innovation, networking, and fun!

• Exclusive Manufacturer Exhibits

• Live Product Demonstrations

• Connect with Industry Leaders

- Minimize Disruptions & Ensure Continuous Production

- Increase Efficiency, Productivity, & Sustainability

- Create a Safer Environment for Workers & Equipment

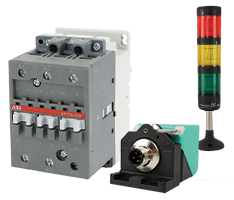

Shop By Category

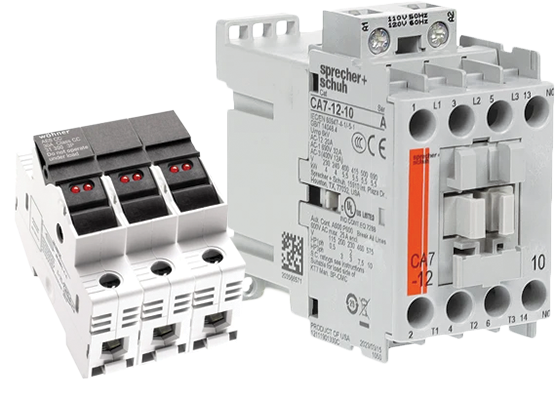

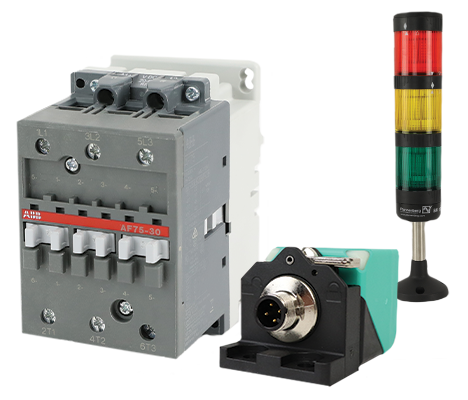

Automation & Control

Circuit Protection

Connectors, Cordsets & Terminals

Electronic Components

Enclosures, Fans & Thermal Management

HVAC

Hydraulics & Pneumatics

Lighting & Indication

Motors, Drives & Accessories

Networking & Communication

Power & Electrical

Process & Instrumentation

Robotics

Safety & Signaling

Semiconductors

Relays

Switches

Test & Measurement

Tools, Hardware & Supplies

Repair