-

BA020246071200KTR Couplings, Rotex Series

BA020246071200KTR Couplings, Rotex Series Item NumberBA020246071200MFG Item NumberBA020246071200SeriesROTEXProduct DescriptionROTEX Hub, 1/2in. Bore, 1/8in. KeywaySpecifications

Item NumberBA020246071200MFG Item NumberBA020246071200SeriesROTEXProduct DescriptionROTEX Hub, 1/2in. Bore, 1/8in. KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 1/2 " Hub Design Regular Hub Bore/Major/Outside Diam 12 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020246102800KTR Couplings, Rotex Series

BA020246102800KTR Couplings, Rotex Series Item NumberBA020246102800MFG Item NumberBA020246102800SeriesROTEXProduct DescriptionROTEX Hub, 28mm Bore, 8mm KeywaySpecifications

Item NumberBA020246102800MFG Item NumberBA020246102800SeriesROTEXProduct DescriptionROTEX Hub, 28mm Bore, 8mm KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 28 mm Hub Design Large Hub Bore/Major/Outside Diam 28 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020246001900KTR Couplings, Rotex Series

BA020246001900KTR Couplings, Rotex Series Item NumberBA020246001900MFG Item NumberBA020246001900SeriesROTEXProduct DescriptionROTEX 24/AL/1/19/6/SSSpecifications

Item NumberBA020246001900MFG Item NumberBA020246001900SeriesROTEXProduct DescriptionROTEX 24/AL/1/19/6/SSSpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 19 mm Hub Design Regular Hub Bore/Major/Outside Diam 19 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020246172500KTR Couplings, Rotex Series

BA020246172500KTR Couplings, Rotex Series Item NumberBA020246172500MFG Item NumberBA020246172500SeriesROTEXProduct DescriptionROTEX Hub, 1in. Bore, 1.4in. KeywaySpecifications

Item NumberBA020246172500MFG Item NumberBA020246172500SeriesROTEXProduct DescriptionROTEX Hub, 1in. Bore, 1.4in. KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 1 " Hub Design Large Hub Bore/Major/Outside Diam 25 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020286002800KTR Couplings, Rotex Series

BA020286002800KTR Couplings, Rotex Series Item NumberBA020286002800MFG Item NumberBA020286002800SeriesROTEXProduct DescriptionROTEX 28/AL/1/28/8/SSSpecifications

Item NumberBA020286002800MFG Item NumberBA020286002800SeriesROTEXProduct DescriptionROTEX 28/AL/1/28/8/SSSpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 28 mm Hub Design Regular Hub Bore/Major/Outside Diam 28 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020142100900KTR Couplings, Rotex Series

BA020142100900KTR Couplings, Rotex Series Item NumberBA020142100900MFG Item NumberBA020142100900SeriesROTEXProduct DescriptionROTEX Hub, 9mm Bore, 3mm KeywaySpecifications

Item NumberBA020142100900MFG Item NumberBA020142100900SeriesROTEXProduct DescriptionROTEX Hub, 9mm Bore, 3mm KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 9 mm Hub Design Large Hub Bore/Major/Outside Diam 9 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020196001900KTR Couplings, Rotex Series

BA020196001900KTR Couplings, Rotex Series Item NumberBA020196001900MFG Item NumberBA020196001900SeriesROTEXProduct DescriptionROTEX Hub, 19mm Bore, 6mm KeywaySpecifications

Item NumberBA020196001900MFG Item NumberBA020196001900SeriesROTEXProduct DescriptionROTEX Hub, 19mm Bore, 6mm KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 19 mm Hub Design Regular Hub Bore/Major/Outside Diam 19 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020196071500KTR Couplings, Rotex Series

BA020196071500KTR Couplings, Rotex Series Item NumberBA020196071500MFG Item NumberBA020196071500SeriesROTEXProduct DescriptionROTEX Hub, 5/8in. Bore, 3/16in. KeywaySpecifications

Item NumberBA020196071500MFG Item NumberBA020196071500SeriesROTEXProduct DescriptionROTEX Hub, 5/8in. Bore, 3/16in. KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 5/8 " Hub Design Regular Hub Bore/Major/Outside Diam 15 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020196001400KTR Couplings, Rotex Series

BA020196001400KTR Couplings, Rotex Series Item NumberBA020196001400MFG Item NumberBA020196001400SeriesROTEXProduct DescriptionROTEX Hub, 14mm Bore, 5mm KeywaySpecifications

Item NumberBA020196001400MFG Item NumberBA020196001400SeriesROTEXProduct DescriptionROTEX Hub, 14mm Bore, 5mm KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 14 mm Hub Design Regular Hub Bore/Major/Outside Diam 14 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BA020196102400KTR Couplings, ROTEX Series

BA020196102400KTR Couplings, ROTEX Series Item NumberBA020196102400MFG Item NumberBA020196102400SeriesROTEXProduct DescriptionROTEX Hub, 24mm Bore, 8mm KeywaySpecifications

Item NumberBA020196102400MFG Item NumberBA020196102400SeriesROTEXProduct DescriptionROTEX Hub, 24mm Bore, 8mm KeywaySpecificationsSpecifications Style Torsionally Flexible Coupling Shaft Size 24 mm Hub Design Large Hub Bore/Major/Outside Diam 24 AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Couplings

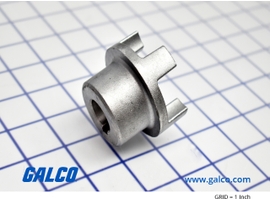

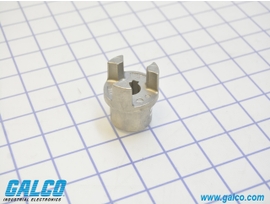

A coupling is a device used to connect two shafts together at their ends to transfer power. Their primary purpose is joining two pieces of rotating equipment together while permitting some degree of misalignment, end movement, or both.

Couplings are most commonly used to transfer power from a motor to a pump, connect shafts of two machines manufactured separately, provide mechanical flexibility, prevent shock and vibrations from transferring from one piece of equipment to another, and potentially slip when torque overload occurs.

They typically feature two rigid parts that fit around the end of two shafts to form a sleeve. A hub sits between the teeth to provide the buffer between each coupling half. Flexible couplings provide similar results with a one-piece aluminum body design to shift under differential torque loads.

Couplings are most commonly used to transfer power from a motor to a pump, connect shafts of two machines manufactured separately, provide mechanical flexibility, prevent shock and vibrations from transferring from one piece of equipment to another, and potentially slip when torque overload occurs.

They typically feature two rigid parts that fit around the end of two shafts to form a sleeve. A hub sits between the teeth to provide the buffer between each coupling half. Flexible couplings provide similar results with a one-piece aluminum body design to shift under differential torque loads.