-

2641005WD11A1CSetra HVAC Sensors, 264 Series

Item Number2641005WD11A1CMFG Item Number2641005WD11A1CSeries264Product DescriptionVery Low Differential PressureSpecifications

Item Number2641005WD11A1CMFG Item Number2641005WD11A1CSeries264Product DescriptionVery Low Differential PressureSpecificationsSpecifications Pressure Range 0-5 in WC Output 4-20 mA Process Connection 3/16 in Dual Barb Fitting Supply Voltage 9-30 VDC Electrical Connection Screw Terminal Temperature Range 0-175 °F RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

C7031D2003/UHoneywell HVAC Sensors, C7031 Series

C7031D2003/UHoneywell HVAC Sensors, C7031 Series Item NumberC7031D2003/UMFG Item NumberC7031D2003/USeriesC7031Product DescriptionPT1000 5IN IMMERSIONSpecifications

Item NumberC7031D2003/UMFG Item NumberC7031D2003/USeriesC7031Product DescriptionPT1000 5IN IMMERSIONSpecificationsSpecifications Application Pipe, Surface Output 1 kOhm PTC Temperature Range (F) -40-350 °F Function Temperature Override No Set Point No RoHS Compliant No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

2651005WDACT1CSetra HVAC Sensors, 265 Series

2651005WDACT1CSetra HVAC Sensors, 265 Series Item Number2651005WDACT1CMFG Item Number2651005WDACT1CSeries265Product DescriptionVery Low Differential PressureSpecifications

Item Number2651005WDACT1CMFG Item Number2651005WDACT1CSeries265Product DescriptionVery Low Differential PressureSpecificationsSpecifications Pressure Range 0-5 in WC Output 0-10 VDC Process Connection 1/4 in Fitting Supply Voltage 9-30 VDC Electrical Connection Screw Terminal Temperature Range 0-150 °F RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

AFS-222Cleveland Controls HVAC Sensors, AFS Series

Item NumberAFS-222MFG Item Number18469SeriesAFSProduct DescriptionPressure Switch, Surface Mount,Specifications

Item NumberAFS-222MFG Item Number18469SeriesAFSProduct DescriptionPressure Switch, Surface Mount,SpecificationsSpecifications Pressure Range 0-12 in WC Process Connection 7/16-24 UNS 2A Male Supply Voltage 115-277 VAC Electrical Connection Screw Terminal Temperature Range -40-180 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

540-660BSiemens Building Technologies HVAC Sensors, 1000 Series

540-660BSiemens Building Technologies HVAC Sensors, 1000 Series Item Number540-660BMFG Item Number540-660BSeries1000Product DescriptionTEC RM Sensor-WhiteSpecifications

Item Number540-660BMFG Item Number540-660BSeries1000Product DescriptionTEC RM Sensor-WhiteSpecificationsSpecifications Application Indoor Output 10 kOhm NTC Temperature Range (F) 55-95 °F Function Temperature Override No Set Point No RoHS Compliant No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

2641005WB11T1CSetra HVAC Sensors, 264 Series

2641005WB11T1CSetra HVAC Sensors, 264 Series Item Number2641005WB11T1CMFG Item Number2641005WB11T1CSeries264Product DescriptionVery Low Differential PressureSpecifications

Item Number2641005WB11T1CMFG Item Number2641005WB11T1CSeries264Product DescriptionVery Low Differential PressureSpecificationsSpecifications Output 4-20 mA Process Connection 3/16 in Dual Barb Fitting Supply Voltage 9-30 VDC Electrical Connection Screw Terminal Temperature Range 0-175 °F RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

DFS-221Cleveland Controls HVAC Sensors, DFS Series

DFS-221Cleveland Controls HVAC Sensors, DFS Series Item NumberDFS-221MFG Item Number18407SeriesDFSProduct DescriptionPressure Switch, Fixed SetpointSpecifications

Item NumberDFS-221MFG Item Number18407SeriesDFSProduct DescriptionPressure Switch, Fixed SetpointSpecificationsSpecifications Pressure Range 0-0.05 in WC Process Connection 1/4 in Slip-On Connector Supply Voltage 115-277 VAC Electrical Connection Spade Temperature Range -40-180 °F RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

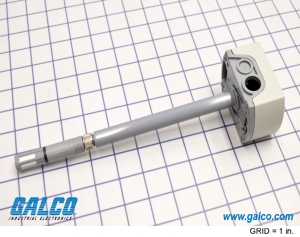

TE-701-BX-7-BMAMAC Systems HVAC Sensors, TE701-BX Series

TE-701-BX-7-BMAMAC Systems HVAC Sensors, TE701-BX Series Item NumberTE-701-BX-7-BMFG Item NumberTE-701-BX-7-B-MAMASeriesTE701-BXProduct DescriptionDuct Temp Sensor, Flange Mount,Specifications

Item NumberTE-701-BX-7-BMFG Item NumberTE-701-BX-7-B-MAMASeriesTE701-BXProduct DescriptionDuct Temp Sensor, Flange Mount,SpecificationsSpecifications Application Duct, Immersion Output 10 kOhm NTC Humidity Sensor No Temperature Range (F) -40-210 °F Probe Length (in) 6 " Function Temperature Override No Set Point No RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

PR-274-R2-VDCMAMAC Systems HVAC Sensors, PR-274 Series

PR-274-R2-VDCMAMAC Systems HVAC Sensors, PR-274 Series Item NumberPR-274-R2-VDCMFG Item NumberPR-274-R2-VDC-MAMASeriesPR-274Product DescriptionLow Pressure Sensor,Specifications

Item NumberPR-274-R2-VDCMFG Item NumberPR-274-R2-VDC-MAMASeriesPR-274Product DescriptionLow Pressure Sensor,SpecificationsSpecifications Pressure Range 0-1 in WC, 0-.5 in WC, 0-.25 in WC, -.5-.5 in WC, -.25-.25 in WC, -.125-.125 in WC Process Connection 1/8 NPT Supply Voltage 12-35 VDC Electrical Connection Terminal Block IP Rating IP65 Temperature Range 0-180 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

AFS-145Cleveland Controls HVAC Sensors, AFS Series

AFS-145Cleveland Controls HVAC Sensors, AFS Series Item NumberAFS-145MFG Item Number18370SeriesAFSProduct DescriptionPressure Switch, Surface Mount,Specifications

Item NumberAFS-145MFG Item Number18370SeriesAFSProduct DescriptionPressure Switch, Surface Mount,SpecificationsSpecifications Pressure Range 0-12 in WC Process Connection 1/8-27 in NPT Female Supply Voltage 115-277 VAC Electrical Connection Screw Terminal Temperature Range -40-180 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

HVAC Sensors

An HVAC sensor is any device used to measure the conditions of an enclosed space, room, or building. HVAC sensors include thermostats, humidistats, carbon dioxide sensors, pressure sensors, and more.

HVAC sensors are connected to equipment and regulate air quality. Thermostats measure temperature, switching on and off heaters and air conditioners so that the measured temperature matches a predetermined setpoint. Humidistats measure humidity and work with thermostats and heaters to protect equipment from condensation and corrosion. Carbon dioxide sensors monitor the quality of the air and regulate fresh air with ventilation adjustments. Pressure sensors monitor and adjust airflow.

HVAC sensors are ultimately responsible for the efficiency of the entire HVAC system and the overall air quality of the environment.

HVAC sensors are connected to equipment and regulate air quality. Thermostats measure temperature, switching on and off heaters and air conditioners so that the measured temperature matches a predetermined setpoint. Humidistats measure humidity and work with thermostats and heaters to protect equipment from condensation and corrosion. Carbon dioxide sensors monitor the quality of the air and regulate fresh air with ventilation adjustments. Pressure sensors monitor and adjust airflow.

HVAC sensors are ultimately responsible for the efficiency of the entire HVAC system and the overall air quality of the environment.