-

KDRMA7L1TCI Line Reactors, KDR Series

KDRMA7L1TCI Line Reactors, KDR Series Item NumberKDRMA7L1MFG Item NumberKDRMA7L1SeriesKDRProduct DescriptionReactor, 480V, 4.2A, 3-PH, Open, 3pct., ULSpecifications

Item NumberKDRMA7L1MFG Item NumberKDRMA7L1SeriesKDRProduct DescriptionReactor, 480V, 4.2A, 3-PH, Open, 3pct., ULSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 4.2 A Inductance 0.0065 H Watt Loss 23.5 W HP @ 480 VAC 2 hp Impedance @ 480 VAC 3 % AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

KDRF3LTCI Line Reactors, KDR Series

KDRF3LTCI Line Reactors, KDR Series Item NumberKDRF3LMFG Item NumberKDRF3LSeriesKDRProduct DescriptionREACTOR 480V 75HP LOW ZSpecifications

Item NumberKDRF3LMFG Item NumberKDRF3LSeriesKDRProduct DescriptionREACTOR 480V 75HP LOW ZSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 96 A Watt Loss 193 W HP @ 480 VAC 75 hp Impedance @ 480 VAC 3 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RLW-001103MTE Line Reactors, RLW Series

RLW-001103MTE Line Reactors, RLW Series Item NumberRLW-001103MFG Item NumberRLW-001103SeriesRLWProduct DescriptionReactor, 11A, 2.100mH, 3Ph, OpenSpecifications

Item NumberRLW-001103MFG Item NumberRLW-001103SeriesRLWProduct DescriptionReactor, 11A, 2.100mH, 3Ph, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 11 A Inductance 0.0021 H Watt Loss 40.9 W HP @ 240 VAC 3 hp Impedance @ 240 VAC 5 % HP @ 480 VAC 7.5 hp Impedance @ 480 VAC 3 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-01803MTE Line Reactors, RL Series

RL-01803MTE Line Reactors, RL Series Item NumberRL-01803MFG Item NumberRL-01803SeriesRLProduct DescriptionReactor, 18A, 2.500mH, 3PH, OpenSpecifications

Item NumberRL-01803MFG Item NumberRL-01803SeriesRLProduct DescriptionReactor, 18A, 2.500mH, 3PH, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 18 A Inductance 0.0025 H Watt Loss 43 W HP @ 480 VAC 10 hp Impedance @ 480 VAC 5 % HP @ 600 VAC 15 hp Impedance @ 600 VAC 5 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RLW-01P105MTE Line Reactors, RLW Series

RLW-01P105MTE Line Reactors, RLW Series Item NumberRLW-01P105MFG Item NumberRLW-01P105SeriesRLWProduct DescriptionReactor, 1.1A, 33.000mH, 3Ph, OpenSpecifications

Item NumberRLW-01P105MFG Item NumberRLW-01P105SeriesRLWProduct DescriptionReactor, 1.1A, 33.000mH, 3Ph, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 1.1 A Inductance 0.033 H Watt Loss 10.1 W HP @ 480 VAC 0.25 hp Impedance @ 480 VAC 3 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-05503MTE Line Reactors, RL Series

RL-05503MTE Line Reactors, RL Series Item NumberRL-05503MFG Item NumberRL-05503SeriesRLProduct DescriptionReactor, 55A, 0.850mH, 3PH, OpenSpecifications

Item NumberRL-05503MFG Item NumberRL-05503SeriesRLProduct DescriptionReactor, 55A, 0.850mH, 3PH, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 55 A Inductance 0.00085 H Watt Loss 71 W HP @ 480 VAC 40 hp Impedance @ 480 VAC 5 % HP @ 600 VAC 50 hp Impedance @ 600 VAC 5 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-01202MTE Line Reactors, RL Series

RL-01202MTE Line Reactors, RL Series Item NumberRL-01202MFG Item NumberRL-01202SeriesRLProduct DescriptionReactor, 12A, 2.500mH, 3PH, OpenSpecifications

Item NumberRL-01202MFG Item NumberRL-01202SeriesRLProduct DescriptionReactor, 12A, 2.500mH, 3PH, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 12 A Inductance 0.0025 H Watt Loss 31 W HP @ 240 VAC 3 hp Impedance @ 240 VAC 5 % HP @ 480 VAC 7.5 hp Impedance @ 480 VAC 3 % Impedance @ 600 VAC 3 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-00402MTE Line Reactors, RL Series

RL-00402MTE Line Reactors, RL Series Item NumberRL-00402MFG Item NumberRL-00402SeriesRLProduct DescriptionReactor, 4A, 6.500mH, 3PH, OpenSpecifications

Item NumberRL-00402MFG Item NumberRL-00402SeriesRLProduct DescriptionReactor, 4A, 6.500mH, 3PH, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 4 A Inductance 0.0065 H Watt Loss 20 W Impedance @ 240 VAC 5 % HP @ 480 VAC 2 hp Impedance @ 480 VAC 3 % Impedance @ 600 VAC 1.5 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-08002MTE Line Reactors, RL Series

RL-08002MTE Line Reactors, RL Series Item NumberRL-08002MFG Item NumberRL-08002SeriesRLProduct DescriptionReactor, 80A, 0.400mH, 3PH, OpenSpecifications

Item NumberRL-08002MFG Item NumberRL-08002SeriesRLProduct DescriptionReactor, 80A, 0.400mH, 3PH, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 80 A Inductance 0.0004 H Watt Loss 86 W HP @ 240 VAC 20 hp Impedance @ 240 VAC 5 % Impedance @ 480 VAC 3 % Impedance @ 600 VAC 3 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

RL-00104MTE Line Reactors, RL Series

RL-00104MTE Line Reactors, RL Series Item NumberRL-00104MFG Item NumberRL-00104SeriesRLProduct DescriptionReactor, 1A, 18.000mH, 3Ph, OpenSpecifications

Item NumberRL-00104MFG Item NumberRL-00104SeriesRLProduct DescriptionReactor, 1A, 18.000mH, 3Ph, OpenSpecificationsSpecifications Phase 3 Enclosed Unit No Current Rating 1 A Inductance 0.018 H Watt Loss 9.6 W HP @ 480 VAC 0.25 hp Impedance @ 480 VAC 1.5 % Mounting Surface AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

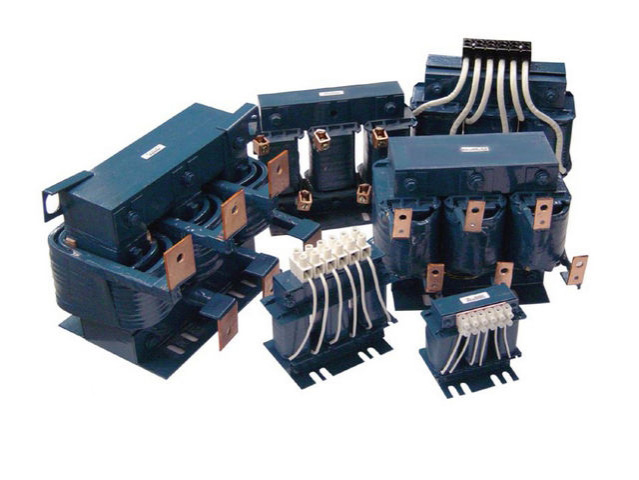

Line Reactors

A line reactor is an inductor wired in series between a power source and a load. It is generally used in motor drive applications to reduce harmonics, limit inrush current, and protect both the motor and the drive.

Line reactors also filter current waveforms and attenuate noise, which helps eliminate nuisance tripping and increase motor drive efficiency.

When installed on the line side of the drive, line reactors are particularly effective at protecting the drive from overvoltage tripping where impedance might otherwise be too low to counteract voltage spikes. When installed on the load side of the drive, line reactors can manage the peak voltage experienced at motor terminals, protecting motor insulation and extending the life the motor.

Line reactors also filter current waveforms and attenuate noise, which helps eliminate nuisance tripping and increase motor drive efficiency.

When installed on the line side of the drive, line reactors are particularly effective at protecting the drive from overvoltage tripping where impedance might otherwise be too low to counteract voltage spikes. When installed on the load side of the drive, line reactors can manage the peak voltage experienced at motor terminals, protecting motor insulation and extending the life the motor.