-

CD3450Baldor Motors, SHUNT WOUND SCR Series

CD3450Baldor Motors, SHUNT WOUND SCR Series Item NumberCD3450MFG Item NumberCD3450SeriesSHUNT WOUND SCRProduct DescriptionMotor, DC, 0.5HP, 1750RPM, 56C,Specifications

Item NumberCD3450MFG Item NumberCD3450SeriesSHUNT WOUND SCRProduct DescriptionMotor, DC, 0.5HP, 1750RPM, 56C,SpecificationsSpecifications Base RPM 1,750 RPM Frame 56C Armature Voltage 90 V Armature Current 5.7 A Enclosure Type Totally Enclosed Fan Cooled Mounting Type C-Face Removable Base CT Speed Range 20:1 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

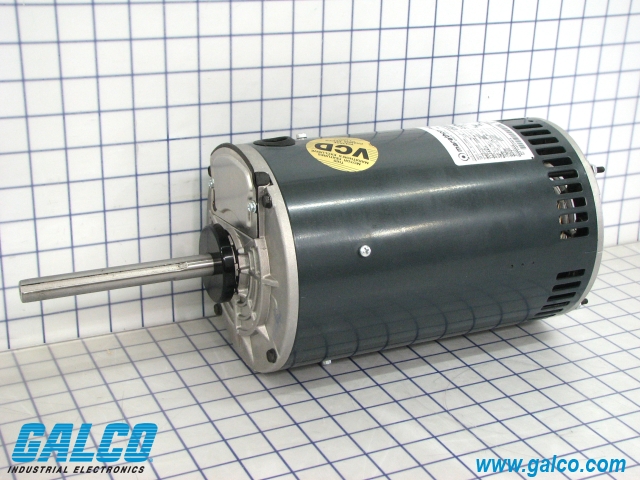

X509Marathon Electric Motors

X509Marathon Electric Motors Item NumberX509MFG Item Number056T11O5304Product DescriptionHVAC MOTORS, 2 HPSpecifications

Item NumberX509MFG Item Number056T11O5304Product DescriptionHVAC MOTORS, 2 HPSpecificationsSpecifications Kilowatts 1.5 kW RPM 1,140 RPM Number of Poles 6 Phase 3 Enclosure Open Air Over Mounting Type Round Belly Band Efficiency % 81.5 % Full Load Current 7.2 A Service Factor 1 Composition Rolled Steel Bearing Type Ball Shaft Diameter 0.63 " Overall Length 17.06 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

WPMDC1-18-90V-56CBWorldwide Electric Corporation Motors, WPMDC Series

WPMDC1-18-90V-56CBWorldwide Electric Corporation Motors, WPMDC Series Item NumberWPMDC1-18-90V-56CBMFG Item NumberWPMDC1-18-90V-56CBSeriesWPMDCProduct DescriptionMotor, DC, 1HP, 1800 RPM, 90V, 10.4Specifications

Item NumberWPMDC1-18-90V-56CBMFG Item NumberWPMDC1-18-90V-56CBSeriesWPMDCProduct DescriptionMotor, DC, 1HP, 1800 RPM, 90V, 10.4SpecificationsSpecifications Base RPM 1,800 RPM Frame 56C Armature Voltage 90 V Armature Current 10.4 A Enclosure Type Totally Enclosed Fan Cooled Mounting Type C-Face Removable Base Service Factor 1 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

XVM-6011-TONS-0000Control Techniques Motors, XV Series

XVM-6011-TONS-0000Control Techniques Motors, XV Series Item NumberXVM-6011-TONS-0000MFG Item NumberXVM-6011-TONS-0000SeriesXVProduct DescriptionXV 60MM SRVOMOTO, METRIC MNTG, 11.2LB,Specifications

Item NumberXVM-6011-TONS-0000MFG Item NumberXVM-6011-TONS-0000SeriesXVProduct DescriptionXV 60MM SRVOMOTO, METRIC MNTG, 11.2LB,SpecificationsSpecifications Power Rating (kW) 0.426 kW Voltage 230 VAC Rated Speed 3,000 RPM Max Speed 5,000 RPM Mounting Type Flange Encoder Type Incremental Constant Torque (Nm) 3.65 Nm Peak Torque (Nm) 1.27 Nm Peak Torque (in-oz) 516.8 in-oz Constant Torque (in-oz) 192 in-oz Constant Torque (in-lb) 12 in-lb Peak Torque (in-lb) 32.3 in-lb Brake No Shaft Seal No IP Rating IP55 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

.7536OS3EJPR56J-SWEG Electric Motors

.7536OS3EJPR56J-SWEG Electric Motors Item Number.7536OS3EJPR56J-SMFG Item Number.7536OS3EJPR56J-SProduct DescriptionMotor, AC, 0.75HP, 3600RPM, 208-230Specifications

Item Number.7536OS3EJPR56J-SMFG Item Number.7536OS3EJPR56J-SProduct DescriptionMotor, AC, 0.75HP, 3600RPM, 208-230SpecificationsSpecifications Type General Purpose RPM 3,600 RPM Phase 3 Frequency 60 Hz Voltage (AC) 208 VAC Nominal Voltage 208 VAC Mounting Type Footless Efficiency % 72 % Full Load Current 1.26 A Service Factor 1.5 Composition Steel AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

XVM-606-TONS-0000Control Techniques Motors, XV Series

XVM-606-TONS-0000Control Techniques Motors, XV Series Item NumberXVM-606-TONS-0000MFG Item NumberXVM-606-TONS-0000SeriesXVProduct DescriptionSERVO MOTOR, 200W, 5.6IN-LB TORQUE,Specifications

Item NumberXVM-606-TONS-0000MFG Item NumberXVM-606-TONS-0000SeriesXVProduct DescriptionSERVO MOTOR, 200W, 5.6IN-LB TORQUE,SpecificationsSpecifications Power Rating (kW) 0.218 kW Voltage 230 VAC Rated Speed 3,000 RPM Max Speed 5,000 RPM Mounting Type Flange Encoder Type Incremental Constant Torque (Nm) 1.82 Nm Peak Torque (Nm) 0.69 Nm Peak Torque (in-oz) 257.6 in-oz Constant Torque (in-oz) 98.08 in-oz Constant Torque (in-lb) 6.13 in-lb Peak Torque (in-lb) 16.1 in-lb Brake No Shaft Seal No IP Rating IP55 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

SGMPH-04AAE4CDYaskawa Motors, SGMPH Series

SGMPH-04AAE4CDYaskawa Motors, SGMPH Series Item NumberSGMPH-04AAE4CDMFG Item NumberSGMPH-04AAE4CDSeriesSGMPHProduct DescriptionSGMPH MOTOR. 200V 400W INCR. BRAKESpecifications

Item NumberSGMPH-04AAE4CDMFG Item NumberSGMPH-04AAE4CDSeriesSGMPHProduct DescriptionSGMPH MOTOR. 200V 400W INCR. BRAKESpecificationsSpecifications Mfg. Product Series Sigma 2 Power Rating (kW) 0.4 kW Voltage 200 VAC Servomotor Type Flat, Pancake Rated Speed 3,000 RPM Max Speed 5,000 RPM Mounting Type Flange Encoder Type Incremental Encoder Bit Resolution 13 BIT Constant Torque (Nm) 1.27 Nm Peak Torque (Nm) 3.82 Nm Peak Torque (in-oz) 542 in-oz Constant Torque (in-oz) 180 in-oz Constant Torque (in-lb) 11.24 in-lb Peak Torque (in-lb) 33.8 in-lb Brake Yes IP Rating IP67 AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

EM3546Baldor Motors, M Series

EM3546Baldor Motors, M Series Item NumberEM3546MFG Item NumberEM3546SeriesMProduct Description1HP, 1770RPM, 3PH, 60HZ, 56, 3520M, TEFC, F1, NSpecifications

Item NumberEM3546MFG Item NumberEM3546SeriesMProduct Description1HP, 1770RPM, 3PH, 60HZ, 56, 3520M, TEFC, F1, NSpecificationsSpecifications Type General Purpose RPM 1,800 RPM Phase 3 Enclosure Totally Enclosed Fan Cooled Efficiency % 85.5 % Full Load Current 1.5 A Service Factor 1.15 Inverter Duty No Composition Steel Bearing Type Ball Overload Protection None Overall Length 12.23 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

MSBBAA0050Control Techniques Motors

MSBBAA0050Control Techniques Motors Item NumberMSBBAA0050MFG Item NumberMSBBAA0050Product Description22A (2.5mm2) Power Cable for motor,AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberMSBBAA0050MFG Item NumberMSBBAA0050Product Description22A (2.5mm2) Power Cable for motor,AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

WPMDC14-18-90V-56CBWorldwide Electric Corporation Motors, WPMDC Series

WPMDC14-18-90V-56CBWorldwide Electric Corporation Motors, WPMDC Series Item NumberWPMDC14-18-90V-56CBMFG Item NumberWPMDC14-18-90V-56CBSeriesWPMDCProduct DescriptionMotor, DC, 1/4 HP, 1800 RPM, 90V,Specifications

Item NumberWPMDC14-18-90V-56CBMFG Item NumberWPMDC14-18-90V-56CBSeriesWPMDCProduct DescriptionMotor, DC, 1/4 HP, 1800 RPM, 90V,SpecificationsSpecifications Base RPM 1,800 RPM Frame 56C Armature Voltage 90 V Armature Current 2.9 A Enclosure Type Totally Enclosed Non-Ventilated Mounting Type C-Face Removable Base Service Factor 1 AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Motors

Electric motors are the backbone of modern automation. Motors convert electrical energy into mechanical energy, and the resulting motion and torque drives a load.

Motors come in all shapes and sizes and are found in a diverse range of applications like industrial fans, blowers, pumps, machine tools, household appliances, power tools, disk drives, conveyors, heavy machinery, robotics, and, more recently, motor vehicles.

For industrial applications, three primary motor types are most common: AC motors, DC motors, and servo motors. AC motors are driven by alternating current, and use electromagnetic induction to apply torque to the rotor. These motors can be single-phase, three-phase, and include several additional variations that serve different purposes. DC motors are powered by direct current, and use applied current and power to vary speed and torque. Servo motors are primarily used with position- or speed-control feedback systems needed for valves, machine tools, and other process systems.

Motors come in all shapes and sizes and are found in a diverse range of applications like industrial fans, blowers, pumps, machine tools, household appliances, power tools, disk drives, conveyors, heavy machinery, robotics, and, more recently, motor vehicles.

For industrial applications, three primary motor types are most common: AC motors, DC motors, and servo motors. AC motors are driven by alternating current, and use electromagnetic induction to apply torque to the rotor. These motors can be single-phase, three-phase, and include several additional variations that serve different purposes. DC motors are powered by direct current, and use applied current and power to vary speed and torque. Servo motors are primarily used with position- or speed-control feedback systems needed for valves, machine tools, and other process systems.